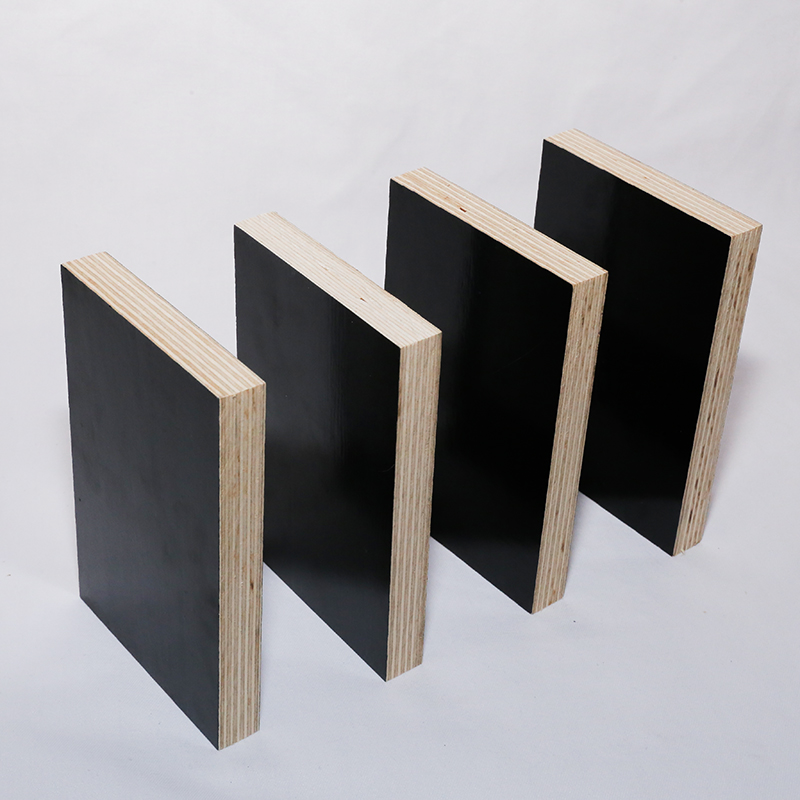

Architectural phenolic zaj duab xis-coated panels haum rau ntau yam kev tsim kho

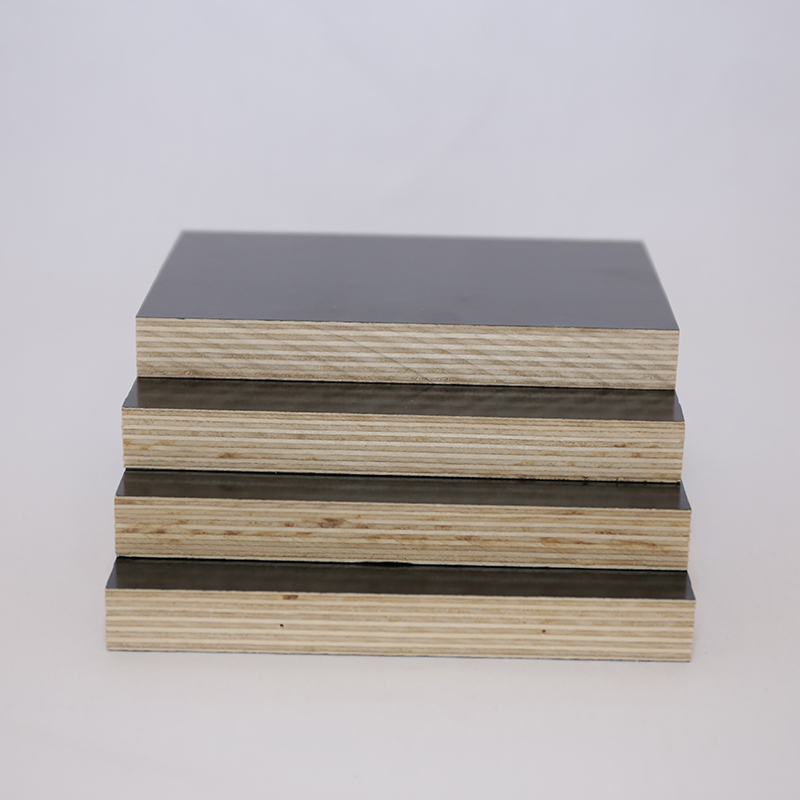

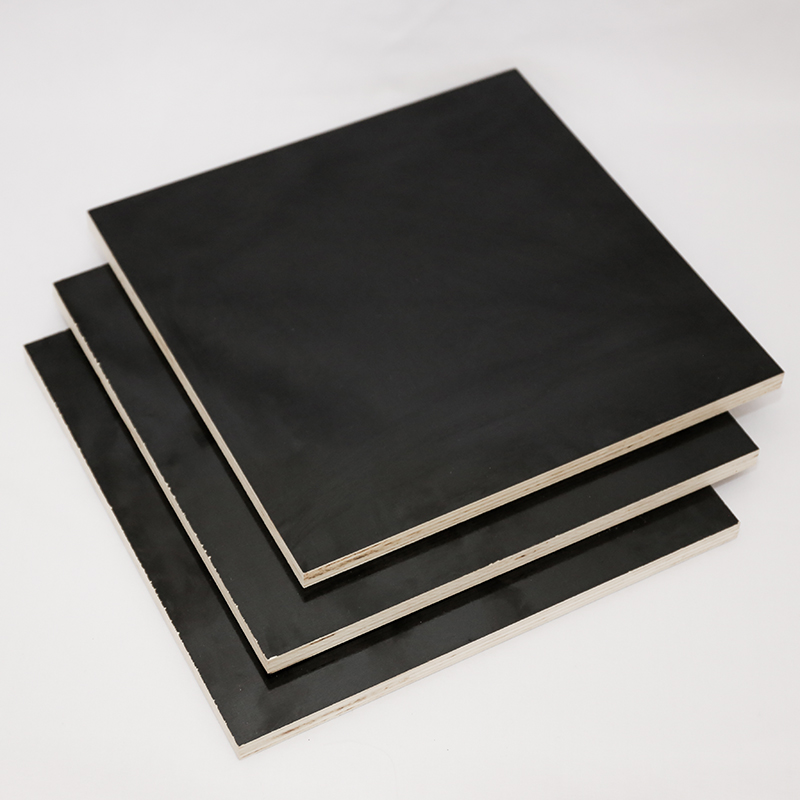

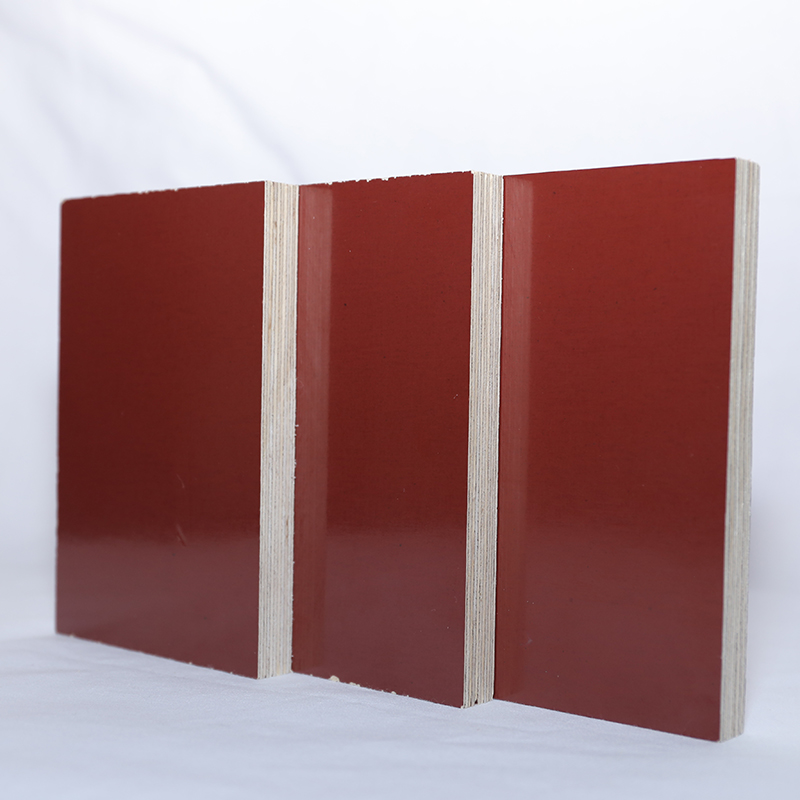

Specifications ntawm lub tsev formwork

1. Cov ntsiab lus tseem ceeb yog: 915x1830mm, 1220x2440mm, 1250x2500mm

2. Thickness: 9mm, 12mm, 15mm, 18mm, 21mm, 24mm ...

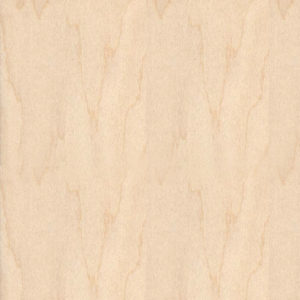

3. Khoom siv: poplar, birch, hardwood, ntoo thuv, mixed ntoo, thiab lwm yam.

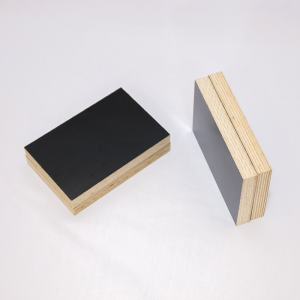

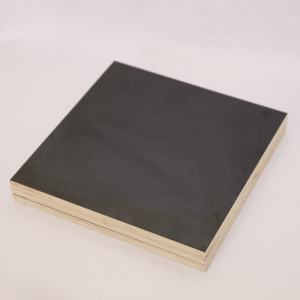

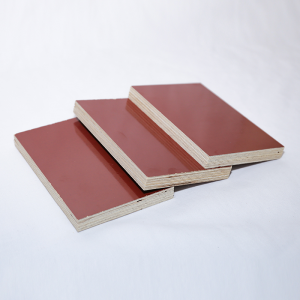

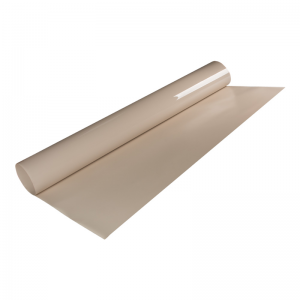

4. Cov kua nplaum hom: phenolic kua nplaum, melamine kua nplaum, kua nplaum tso zis

5. Zaj duab xis ntawv: phenolic coated ntawv xim av zaj duab xis, dub zaj duab xis

Khoom Txheem

| Tus lej | Qhov project | Cov Qauv Khoom | |

| 01 | ntug defect | tsis muaj | |

| 02 | Kaw qhib, tawg, txheej | tsis muaj | |

| 03 | ntev kam rau ua | ± 3 hli | |

| 04 | Thickness kam rau ua | 12 ± 0.2 hli / 15 ± 0.2 hli / 18 ± 0.5 hli | |

| 05 | Diagonal kam rau ua | ± 3 hli | |

| 06 | Warpage | tsis ntau tshaj 1% | |

| 07 | Deg dents, indentations, bulges | tsis muaj (Tshwj xeeb rau tus kheej me ntsis indentations) | |

| 08 | kho qhov chaw | tsis muaj | |

| 09 | Deg khawb, hlawv, burrs | tsis muaj (Tshwj xeeb rau tus kheej me ntsis indentations) | |

| 10 | Cov ntawv laminated yog glued, puas, thiab cov npoo uas ploj lawm | tsis muaj | |

| 11 | kev hloov xim | tsis muaj | |

| 12 | Vaj huam sib luag stitching | tsis muaj | |

| 13 | Vaj Huam Sib Luag Lamination | tsis muaj | |

| 14 | paj, paj | tsis muaj | |

| 15 | noo noo cov ntsiab lus | 6 ~ 8 | |

| 16 | daim ntawv cog lus zog Mpa | Qhov piv ntawm cov qauv tsim nyog rau tag nrho cov qauv siv tau yog ≥90% | ≥0.7 |

| 17 | Ntoo puas tus nqi 39% | ||

| 18 | Static dabtsi yog khoov zog Mpa | nrog grain ≥45 | |

| 19 | kab rov tav kab ≥30 | ||

| 20 | Elastic Modulus | raws li grain ≥6000 | |

| 21 | kab rov tav kab ≥4500 | ||

Lub teeb Weight

Tsim nyog rau cov tsev siab siab thiab kev tsim kho choj.

LojFormat

Cov hom ntawv siab tshaj plaws yog 2440 × 1220mm, uas txo cov pob qij txha thiab txhim kho kev ua haujlwm ntawm cov formwork.

Ntev ntev

Tsis muaj warping, tsis deformation, tsis muaj cracking, zoo dej tsis kam, siab turnover thiab ntev kev pab cuam lub neej.

Yooj yim Demoulding

Lub demoulding yog ib qho yooj yim, tsuas yog 1/7 ntawm cov hlau pwm.

Qhob Pouring

Qhov saum npoo ntawm cov khoom nchuav yog du thiab zoo nkauj, tshem tawm cov txheej txheem plastering thib ob ntawm phab ntsa, nws tuaj yeem ncaj qha veneered rau kho kom zoo nkauj, txo lub sijhawm tsim kho los ntawm 30%.

Corrosion kuj, zoo thermal rwb thaiv tsev kev ua tau zoo

Tsis pollute lub pob zeb nto;conducive rau lub caij ntuj no kev tsim kho.

Kev tsim kho tau zoo

Kev ua haujlwm ntawm nailing, sawing thiab drilling yog zoo dua li ntawm xyoob plywood thiab cov hlau me me.Nws tuaj yeem ua tiav rau hauv ntau yam duab ntawm formwork raws li kev tsim kho xav tau, thiab formwork ntawm lub dav hlau nkhaus.

Siv ntau zaus

Nws tuaj yeem siv tau ntau zaus yog tias khaws cia thiab siv kom raug.

Plaub qhov zoo kom ua tiav lub koob npe nrov thiab pab cov haujlwm zoo

Thaum kawg koj tau pom ib pawg neeg muaj zog, xaiv Chunsen, xaiv qhov zoo

1. Kev paub ntau lawm ntau lawm

Lub tuam txhab muaj ntau xyoo ntawm kev lag luam kev paub thiab ntau tus kws tshaj lij kws tshaj lij.Lub tuam txhab ua raws li lub hauv paus ntsiab lus ntawm kev ua tau zoo ua ntej, thiab nws cov khoom raug muag hauv tsev thiab txawv teb chaws.Nws yog ib lub tuam txhab niaj hnub ua ke nrog kev ua, kev tsim khoom thiab kev muag khoom.

Xyoo ntawm kev lag luam kev lag luam, ua tiav ntau yam ntawm cov khoom.

2. Cov khoom muaj zog

nruj me ntsis xaiv thiab siv cov khoom zoo raw khoom thiab cov khoom siv los xyuas kom meej tias txhua yam khoom tau yug los nrog cov khoom zoo txij thaum pib ntawm kev tsim khoom.

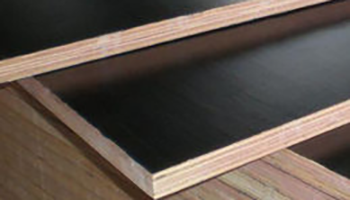

Lub board nto yog tiaj tus thiab du, nrog lub teeb yuag, tsis muaj warping, tsis muaj deformation, tsis muaj cracking, yooj yim demoulding, siab zog, zoo bonding quab yuam thiab ntsia hlau tuav quab yuam los xyuas kom meej cov nyhuv.

Cov dej tsis kam thiab thermal rwb thaiv tsev kev ua tau zoo, cov phaj loj loj, lub voj voog loj thiab siv tau ntev.

Template qhov chaw Hoobkas ncaj muag, tus nqi zoo, kev ruaj ntseg zoo.

3. Ntau lawm muaj zog

20 acres ntawm cov khoom lag luam hauv paus, kev tsim khoom niaj hnub tsim, 5 lab / xyoo ntshiab dej template ntau lawm thiab tsim muaj peev xwm.

Specializing nyob rau hauv zoo, peb muaj advanced plywood manufacturing thiab ua khoom siv ntau lawm kab nyob rau hauv tsev thiab txawv teb chaws.

Kev tsom xam, kev tshawb fawb thiab kev tsim kho customized ntau lawm integrated manufacturers

4. Kev ruaj ntseg zoo

Ua tib zoo xaiv cov khoom siv raw khoom, nkag mus rau hauv lub Hoobkas thiab tom qab ntawd dhau qhov kev tshuaj ntsuam, thiab tswj cov khoom zoo los ntawm qhov chaw.

Tag nrho cov txheej txheem ntawm kev soj ntsuam cov txheej txheem yog zoo meej, cov cim qhia hnyav, thiab nws ua tau raws li lub teb chaws kev soj ntsuam thiab cov qauv ntsuas thiab kev tiv thaiv ib puag ncig.

Cov formwork tau raug sim los ntawm National Supervision and Inspection Center thiab tau mus txog B/T1756-2008 "Standard of Plywood for Concrete" thiab tau txais kev qhuas thiab qhuas los ntawm ntau tog.

Kev tswj xyuas nruj, paub meej hauv cov ntsiab lus, kev tshuaj xyuas tag nrho, kev lees paub tom qab muag.